Automated Backup

Increase backup protection—easily and cost-effectively.

Automated Backup

Increase backup protection—easily and cost-effectively.

Backup is like insurance: You hope you never need to use it, but if you do and don’t have it, you could be in trouble. When it comes to programmable logic controller (PLC) backup, however, implementing backup can be tedious.

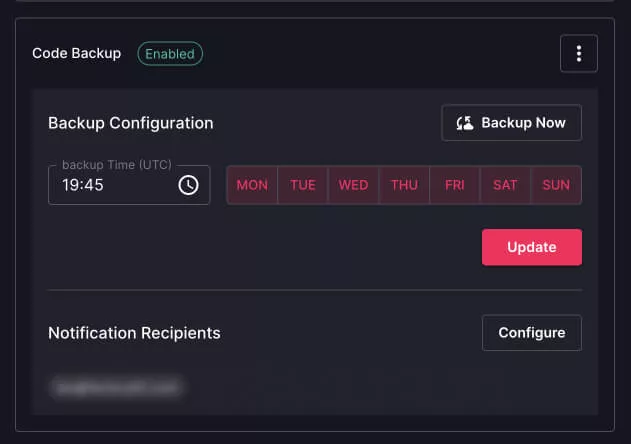

Setting up backups in a secure manner for all the machines on your shop floors is a long and challenging process. Managing backups of the various industrial automation systems takes time and effort—for many automation engineers, backup can consume much of their day. Too often, those backups stay on the shop floor, so they’re not protected from physical damage on-site. A fire, flood, or other disaster within the plant could leave you with nothing to restore from.

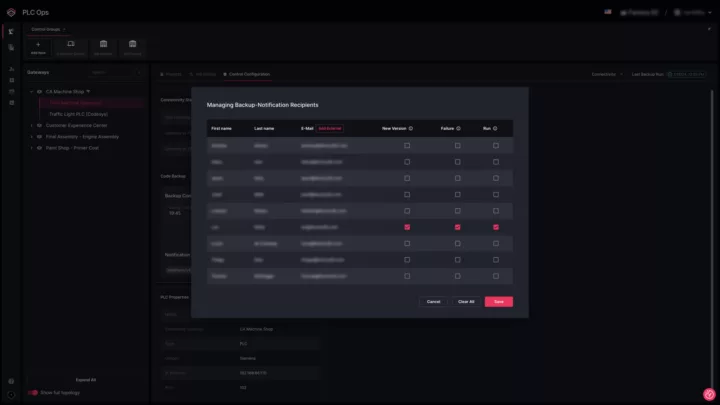

Software Defined Automation gives you maximum backup protection with minimal hassle and expense. Automated Backup delivers simple, secure automated backup and restore—and peace of mind.

Backup in Minutes and Cost-effectively

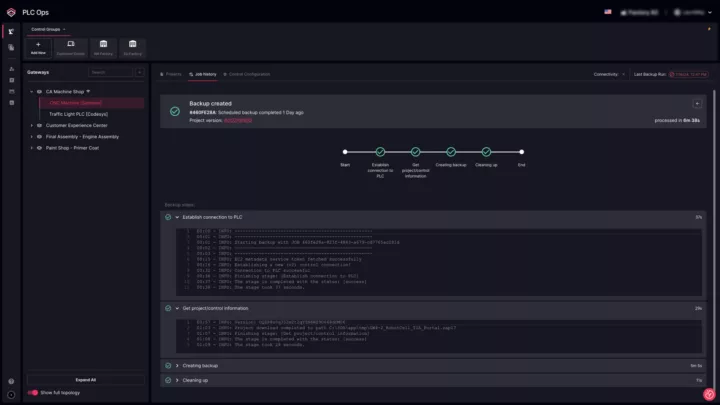

SDA offers a secure, non-intrusive automated backup solution, so you can avoid a lengthy and expensive hardware and software acquisition, provisioning, connection, and configuration effort. Just install our lightweight PLC connectivity agent, and you’re up and running.

Streamline Backups Across Vendors

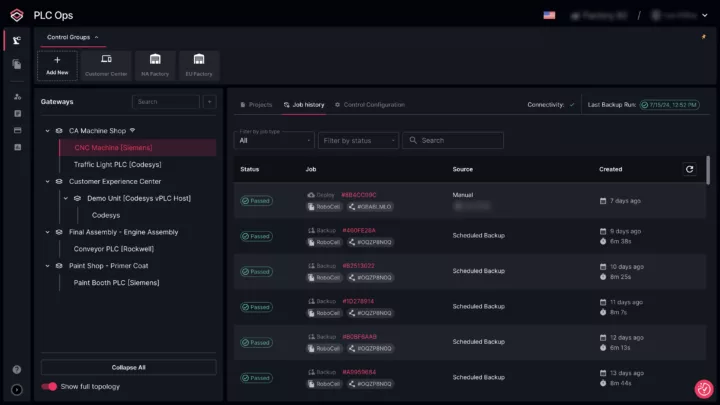

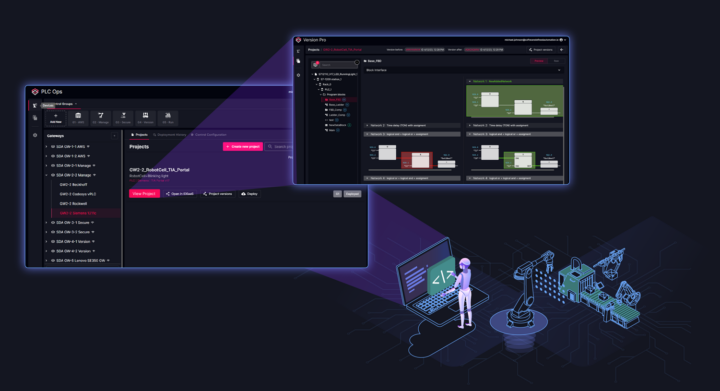

Factories often have operational technology (OT) environments with industrial controllers from different vendors, and then multiple controllers from those vendors with different code versions. Automated Backup is vendor-agnostic, enabling you to manage all your backups from one interface.

Improve Data Resilience

Backup systems and processes often focus on the secure capture and storage of control logic. This is important, but it’s only half of the backup formula.

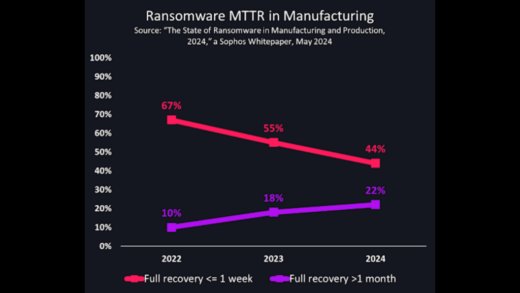

Data resilience—your ability to recover from disruptions or failures—is just as critical.

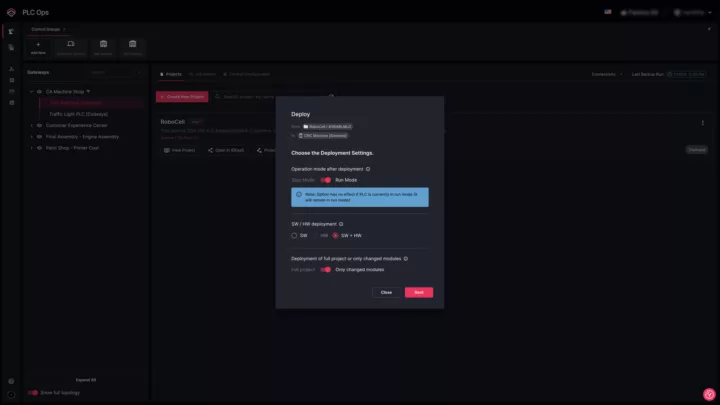

If it’s difficult to access and restore the data, you lengthen your mean time to recover (MTTR) and time to resume operations. SDA provides targeted deployment for point-in-time backups, reducing the time to recover to minutes.

Create Multi-site Backup Visibility and Control

With SDA, you can manage backups across all your factories from a single pane of glass. This ensures backups are executed consistently company-wide, minimizing the potential weak links in your overall business continuity and disaster recovery controls.