Blog

Dear vPLC, how real-time are you?

Note:

This article is a condensed version of the scientific paper we published at the IEEE IES International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Sept. 2022 [9]

Modernizing the factory automation stack requires more than an update of the latest PLC models. Instead, a paradigm shift towards software-defined automation is required [1],[2]. The design and implementation of flexible manufacturing systems for individualized products are crucial for competitive production systems of the future [3],[4],[5]. In such systems, reconfiguration or redeployment of industrial automation systems can be done for every piece, the application of machine learning and artificial intelligence (AI) algorithms is essential, and full-loop feedback systems enable self-optimizing production systems.

Programmable Logic Controllers (PLCs) are widely used throughout industrial automation due to their determinism, quick response times, and robustness. However, current PLCs, along with the way the industry is structured, can’t support future scaling needs [6],[7]. Hardware/Software integrated PLCs do not support resource-demanding tasks, such as algorithms based on machine learning and artificial intelligence. Furthermore, hardware-based PLCs imply individual maintenance and hardware costs, as every single technical process regularly includes an individual PLC for each subsystem [7]. Modern control systems need to meet requirements for operational technologies and information technologies.

Although there have been many incremental innovations to PLCs over the past decades, these have been focused on the integration of improved hardware components, such as more operations per second or newer and faster communication protocols, rather than structural changes to the programming model or the architecture of PLCs.

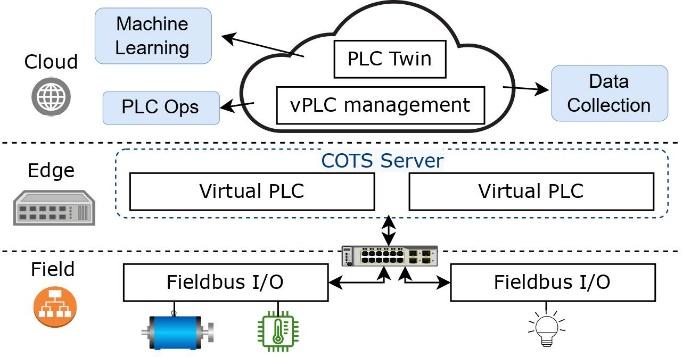

Figure 1:

In a software defined automation, virtual PLCs can be used to control industrial assets in the same way as conventional PLCs do. A COTS server located on the edge can host multiple virtual PLCs to control assets in real-time. Virtual PLCs can be managed and monitored from a cloud instance.

Uncoupling of hardware and software not only allows scaling but also helps to overcome supply chain challenges with proprietary PLC hardware due to the vast availability of standard x86 server hardware. The term virtual PLC refers to a soft PLC that runs within a virtual machine managed by a real-time hypervisor in a commercial-off-the-shelf (COTS) server. Servers and computers can offer enough resources to fulfill the functions of PLCs, Human-Machine Interfaces (HMIs), and programming terminals together [8]. A server hosting virtual PLCs that communicate with the shop floor and cloud (see Fig. 1). Coupling the cloud and shop floor further allows the implementation of software-based PLC operations (Ops), as well as data collection and use of advanced machine learning algorithms, while still satisfying deterministic real-time requirements. Virtual PLCs help overcome the limitations of hardware-based PLCs by offering more flexibility, better resource usage, scalability, and lower costs.

The virtual PLC implementation portrayed in [9] was done using a barebone server, VMWare’s ESXi 7.0 hypervisor, Linux Debian 11, CODESYS SoftPLC runtime, and EtherCAT. As virtualization has the outlined benefits, the million-dollar question is: Does it also fulfill real-time requirements in discrete automation of around 10ms? To measure the real-time performance, we implemented a Virtual PLC (vPLC) architecture and executed extensive performance tests [9]. The results indicate that virtual PLC is a viable option for important domains of factory automation, where response times between 5-10 ms are acceptable [10].

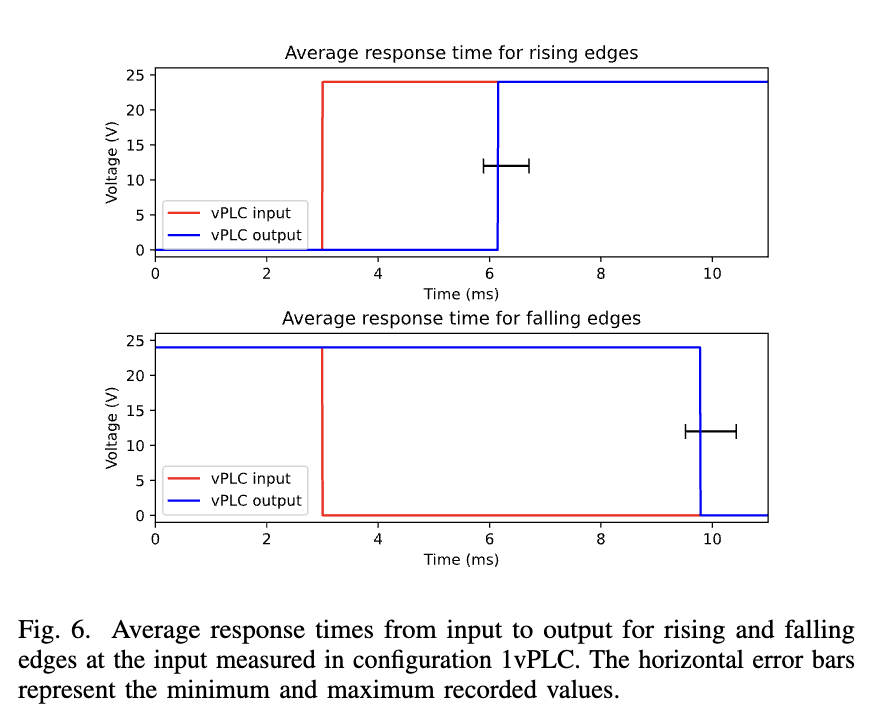

Figure 2:

Average response times from input to output for rising and falling edges at the input. The horizontal error bars represent the minimum and maximum recorded values.

So, what do we learn from this focused research? Dear vPLC, you are real-time enough for most discrete factory automation applications!

- The measured maximum response times suggest that the vPLC can be used in areas of industrial automation in factory automation where response times between 5-10 ms are acceptable.

- Task execution times of the PLC runtimes in the server are within the microseconds range. Therefore, improvements in networking speeds will bring vPLCs down to the motion control range <1ms. [Refer to reference 9 in the full paper].

Sources:

[1] J. Waltl, Unchain the ShopFloor through Software-Defined Automation, May 2018. [Online]. Available: https://www.engineersrule.com/unchainshopfloor-software-defined-automation/ (visited on 04/05/2022).

[2] H. Forbes, The End of Industrial Automation (As We Know It), Dec. 2018. [Online]. Available: https://www.arcweb.com/blog/end-industrialautomation-we-know-it (visited on 04/28/2022).

[3] Y. Koren, The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems. New Jersey: John Wiley & Sons, Ltd, 2010, pp. 227–252.

[4] I. Garbie and A. Garbie, “Outlook of requirements of manufacturing systems for industry 4.0,” in 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, Feb. 2020, pp. 1–6.

[5] S. Vaidya, P. M. Ambad, and S. M. Bhosle, “Industry 4.0 a glimpse,” Procedia Manufacturing, vol. 20, pp. 233–238, 2018.

[6] R. Langmann and M. Stiller, “Cloud-based industrial control services: The next generation PLC,” in Online Engineering & Internet of Things. Lecture Notes in Networks and Systems. Cham: Springer International Publishing, 2018, vol. 22, pp. 3–18.

[7] P. Gaj, J. Jasperneite, and M. Felser, “Computer communication within industrial distributed environment a survey,” IEEE Transactions on Industrial Informatics, vol. 9, no. 1, pp. 182–189, Jul. 2013.

[8] E. R. Alphonsus and M. O. Abdullah, “A review on the applications of programmable logic controllers (PLCs),” Renewable and Sustainable Energy Reviews, vol. 60, pp. 1185–1205, Feb. 2016.

[9] D. Perez, L. Prenzel, J. Waltl and S. Steinhorst, “How Real (Time) Are Virtual PLCs?”, in IEEE IES International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Sept. 2022.

[10] PROFIBUS International, “PROFINET Real-Time Communication,” Tech. Rep., 2013.

Stay up to date. Subscribe for our latest news.